Your Playbook for Procuring Injection Molding Services from China

So, the big meeting just wrapped up. your new product is a go, the timeline is aggressive, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. The cost savings can be huge. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

Here’s the thing, though. Sourcing China injection molding doesn’t have to be a gamble. It’s no different from any structured project. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. The replies will range from absurdly low to exorbitant, none of which help.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. It’s the cornerstone of your entire effort.

So, what goes in it?

First, your 3D CAD files. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

But 3D isn’t enough. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Don’t label it simply “Plastic.” Nor just “ABS.” Be specific. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Lastly, add your business data. State your EAU. A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Now that your RFQ is pristine. now, who do you send it to? Online sourcing is global but crowded. Locating vendors is easy; vetting them is the real challenge.

You’ll probably kick off on Alibaba or Made-in-China. They offer breadth but not depth. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Consider using a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Consider it timeline insurance.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. Also, leverage the tried-and-true referral network. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How do you do that? It blends technical checks with intuition.

Step one: audit communication. Are their replies prompt and clear? Do they communicate effectively in English? The true litmus: are they raising smart queries? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. You know they know their stuff. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. You can’t skip this. As you vet staff, you must vet suppliers. You can travel or outsource a local inspector. They’ll send a local inspector to the factory for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

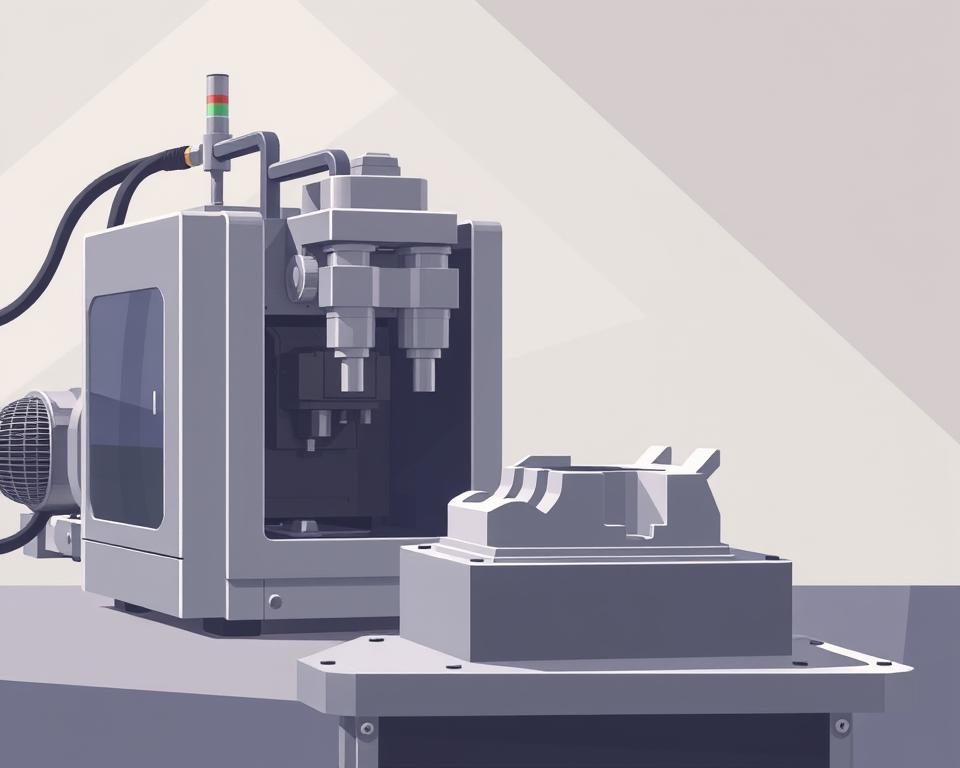

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These are the very first parts off the new tool. It’s your test of success.

Expect T1s to need tweaks. It’s par for the course. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. Plan for this loop in your schedule.

Finally, a flawless part arrives. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now you’re entering the mass production phase. How do you ensure that the 10,000th part is just as good as the golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They’ll send you a detailed report with photos and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

Sourcing from China is a marathon, not a sprint. It relies on partnership-building. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.