AMT Singapore: Ultra-Precise Plastic Injection Molding.

A tiny medical component can demand extreme accuracy while still being mass-produced—did you know? This high level of detail is crucial for industries like medical, car, and electronics. They look for dependable partners in Singapore.

With roots in 1990, AMT brings over three decades of partnership to manufacturers. They combine precision toolmaking, tuned plastic molding, micro-molding, and CNC machining. That consolidation reduces supplier count and accelerates time-to-market.

With reach in 30+ countries, AMT maintains best-in-class https://amt-mat.com/guide-on-high-precision-plastic-injection-molding facilities. Safety and reliability anchor their manufacturing, notably for medical devices. Attention to detail and high precision plastic injection molding positions them as a Singapore go-to for quality and consistency.

What is Precision Plastic Injection Molding and why it matters in Singapore

Precision plastic injection molding offers rapid production with consistent quality. Pellets are melted and injected into a mold under high pressure. It enables complex geometries and fine features beyond many alternative processes.

Core Concepts of Injection Molding

It’s a balance of resin selection, tooling design, and machine control. Resin selection drives mechanical performance and flow characteristics. Mold design ensures accuracy through proper venting and cooling. And, precise machine control guarantees consistent production.

Relevance to Singapore OEMs and Manufacturers

Singapore’s medical, electronics, and automotive sectors require highly reliable components. By combining tooling with molding, AMT streamlines builds. That helps Singapore firms meet regulations and protect IP.

Performance Metrics That Matter

With disciplined process/tooling, tolerances to ±10 µm are achievable. Advanced cooling shortens cycles and cuts cost while maintaining quality. Automation and early detection lift yields and minimize rework.

| Metric | Common Target | Impact on Manufacturing |

|---|---|---|

| Dimensional Tolerance | ±10–100 µm | Controls fit/function and assembly consistency in precision parts |

| Shot Cycle Time | 2–60 seconds per shot | Drives throughput, lead times, and unit economics at volume |

| First-Pass Yield | 95–99.9% | Reduces scrap/warranty risk and boosts efficiency |

| Traceability | Batch→Serial | Enables audits and warranty handling for regulated parts |

| Run Customization | Low–high volume capable | Supports tailored solutions via DFM and custom manufacturing |

Precision molding indicates integrated, high-quality production. For Singaporean companies, this means cost savings, fewer vendors, and quicker market entry. It’s a smart choice for staying competitive.

AMT and precision plastic injection molding

As a partner, AMT simplifies complex supply chains. It combines tooling, molding, and assembly to shorten lead times. This means less waiting and more doing for clients, with one point of contact for everything.

Strategic Contract Manufacturing with AMT

Across medical, automotive, and electronics, AMT delivers integrated solutions. It helps original equipment manufacturers (OEMs) and contract manufacturers bring designs to life. Teams trust AMT for reliable support from start to finish.

AMT Experience and Global Footprint

AMT has grown and innovated for more than three decades. Today they serve customers in 30+ countries. Roughly 350 employees power product development, precision molding, and complex assemblies.

The company holds 29 patents and 15 inventions, proving its commitment to innovation especially in microfluidic technology and automotive parts.

Certifications Backing Precision: ISO 9001 / 13485 / IATF 16949

AMT meets customers’ high standards thanks to solid regulatory and quality credentials. ISO 9001 certification demonstrates adherence to quality management systems. The ISO 13485 certification means it meets the stringent requirements for medical device production. IATF 16949 ensures alignment with automotive standards for traceability and defect prevention.

These certifications position AMT as a leading company for precision plastic injection molding. Be it precision molding or custom plastic manufacturing, AMT is a go-to. It offers the capabilities to scale and ensure compliance through every step of the product lifecycle.

AMT: Specialized Capabilities & Technologies

High-precision tooling and molding for medical/auto/electronics define AMT Singapore. It boasts Class 10,000 and Class 100,000 cleanroom production facilities. The setup minimizes contamination and supports micro-scale work.

Micro molding is perfect for creating very small parts needed in diagnostics and wearable technology. AMT operates advanced micro-molding injection machines. They produce highly accurate, consistent parts—even with complex geometries.

For volume runs, high-cavitation precision molding is key at AMT. Tooling is engineered for uniform thermal control and precise gate placement. This guarantees a consistent surface finish and uniform dimensions throughout large batches.

Multi-shot molding at AMT boosts design flexibility. Parts can feature overmolded seals, multi-colors, and integrated hinges via multi-shot/2K. Additionally, auto insert molding incorporates metal or ceramic inserts in one go, ensuring robust connections.

Rapid heat/cool tooling shortens cycles and improves complex part aesthetics. Overmolding adds soft elastomers to rigid substrates. These approaches demonstrate AMT’s commitment to precise molding in regulated sectors.

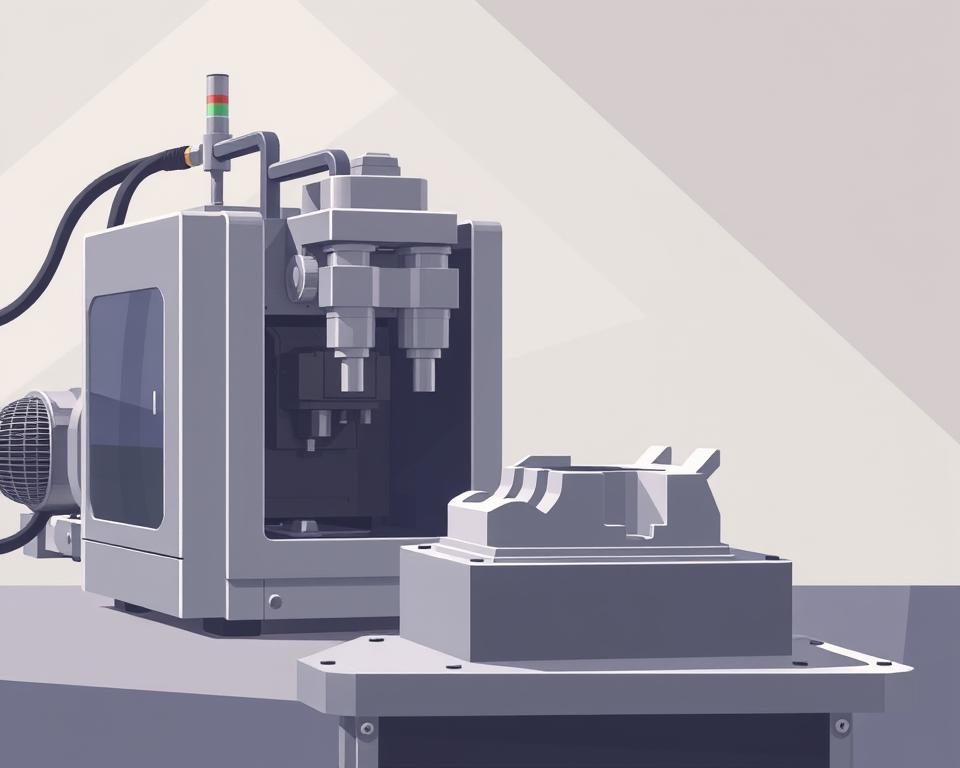

Exacting standards are maintained via process control and in-house CNC. It allows rapid tooling refinements. By integrating micro molding, high cavitation precision molding, and multi-shot techniques, AMT aids designers in moving from prototypes to production efficiently and cost-effectively.

Materials & Sustainability Options at AMT

Material choices weigh performance alongside eco-friendliness. They pick materials in the early stages, focusing on what works best in different fields like medicine, cars, and electronics.

Common thermoplastics and specialty polymers

ABS, PC, and nylon suit durable parts. PEEK and Ultem are great for jobs requiring resistance to heat and maintaining shape. For unique needs, specialty polymers are selected for their mechanical, chemical, and electrical properties.

Sustainable Material Options

Where feasible, AMT uses recycled plastics. Reclaimed resins reduce footprint without sacrificing performance in many cases. PLA/PHA are considered where spec and regulation allow.

Sector-Specific Material Considerations

For medical parts, the materials have to be safe for the body, sterilizable, and fully traceable. AMT enforces strict rules in cleanrooms to ensure patient safety.

In the auto industry, materials must withstand heat, chemicals, and shaking. AMT evaluates durability and thermal behavior.

Electronics require low outgassing, flame resistance, and dimensional stability. The choice of material affects how well the product works, its assembly success, and how it looks.

Environmental targets lead AMT to account for lifecycle and recycling. Tooling/material expertise allows recycled/biodegradable use without compromising quality.

From design to delivery: AMT’s end-to-end production workflow

AMT takes your idea from a CAD drawing to a finished part, focusing on precision every step of the way. They start with design reviews and manufacturability checks. Engineers refine wall thickness, ribs, and features for speed and robust function.

Design & DFM

Computer simulations predict design performance. This early testing helps avoid extra changes and keeps costs down. Goal: ensure molded parts match the initial design closely.

Tooling & Mold Fabrication

Molds are built precisely with tools such as 5-axis CNC. Strict procedures and robust steels yield long-life molds.

Assembly and cleanroom handling

Parts undergo assembly, welding, and rigorous inspection after molding. They have special clean rooms for assembling parts that must be kept free from contaminants.

| Production Stage | Key activities | Benefits |

|---|---|---|

| CAD & DFM | Simulation, wall optimization, tolerance strategy | Reduced revisions and predictable molding |

| Tool making | 5-axis CNC, EDM, wire-cut, precision grinding | Precise, durable molds with consistent cavities |

| Molding | Micro and standard presses, process validation | Repeatability, low scrap, controlled cycles |

| Assembly/Inspection | Robotics, cleanroom handling, traceable inspection | Audit readiness, sterility, full traceability |

Keeping tooling through molding under one roof reduces waits and simplifies the process. A single accountable partner makes design→production simpler, more reliable, and more cost-effective.

Using sophisticated injection molding, they create parts that exactly meet your needs. These parts are used in important industries like healthcare, automotive, and electronics not just in Singapore, but across the region.

Quality Assurance & Testing for High-Precision Outcomes

AMT Singapore keeps tooling, molding, assembly, and inspection together. It provides full traceability and satisfies strict medical/auto requirements. Teams follow ISO 13485/IATF 16949 methods to keep steps clear and repeatable.

Real-time production data is captured. Sensor data drives quick corrections and efficiency gains.

Robots inspect quickly and accurately with consistent force and lighting. Findings link immediately to part history, speeding up issue handling.

Dimensional checks are key; metrology confirms tiny features accurately. Results support batch traceability and performance understanding.

Traceability extends back to materials, with full records. Such detail helps meet US FDA and EU regulatory expectations.

ISO 13485 and IATF 16949-aligned systems cover design, risk, and suppliers. High quality is sustained via audits and rigorous procedures.

Applications & Use Cases AMT Serves in Singapore

AMT provides specialized solutions across industries in Singapore, moving projects from prototype to mass production effectively. Cleanrooms plus vertical integration make AMT a top option for medical devices and quality plastics.

Medical groups work with AMT on microfluidic chips and single-cell cartridges. They produce small optical parts needing precise tolerances and clarity, with cleanrooms and ISO 13485-aligned processes reducing contamination risks.

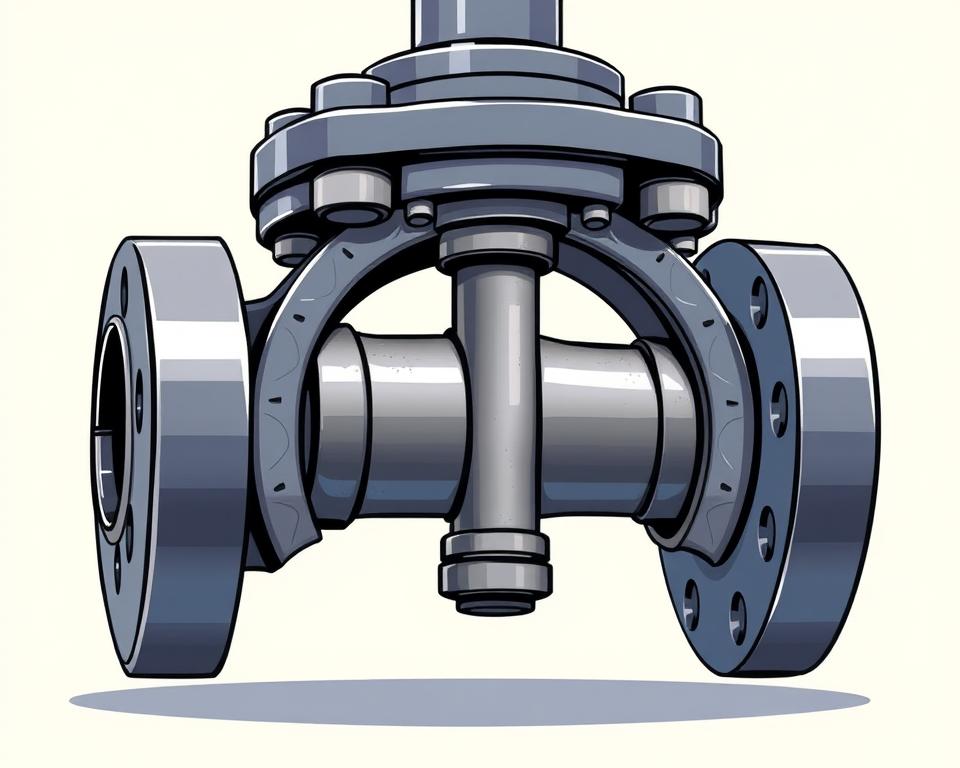

AMT supplies automotive connectors/fittings aligned with IATF 16949. Applications span fuel systems, safety housings, and connectors with durability and traceability designed in.

Electronics companies get micro housings, connectors, and components from AMT for both consumer and industrial items. Advanced molding keeps quality consistent to electrical/mechanical specs.

Here’s a concise industry-by-industry view of applications, requirements, and strengths.

| Industry | Applications | Requirements | Strengths |

|---|---|---|---|

| Healthcare | Microfluidic chips, single-cell cartridges, lens-care inserts | Biocompatibility, low particulates, clarity, full traceability | ISO 13485, cleanrooms, precision tooling |

| Automotive | Electrical connectors, fuel-system fittings, safety housings | Durability, vibration resistance, dimensional stability | IATF workflows, robust materials, traceable production |

| Electronics | Micro housings, precision connectors, EMI shields | Tight tolerances, fine finish, repeatable accuracy | High-cavitation molding, multi-shot capability, in-line inspection |

Singapore manufacturers favor AMT for scalable high-precision components. OEMs looking for a reliable plastic injection molding partner find that AMT’s comprehensive services streamline time to market and safeguard design integrity.

Industry 4.0 and Advanced Manufacturing at AMT

In Singapore, makers are upgrading to interconnected workshops, using 3D metal printing and precise toolsets with digital flows. This makes new manufacturing methods work for big and small production.

Sensorized molds stream temperature/pressure in real time and adjust on-the-fly to issues. This quick fix reduces stoppages and enhances surface looks.

Robotics perform consistent handling, sorting, and QC—ensuring good parts early and reducing manual touches.

By analyzing data, manufacturers spot minor issues before they turn into big problems, tweaking the process based on past and current data to keep product quality consistent.

Innovations in molding and sensor control make manufacturing faster while keeping quality. Dashboards surface KPIs for quick informed decisions on the floor.

Research and strong property rights support these methods. Patents in metal powders/tools signal deep commitment to new methods, driving better outcomes with Industry 4.0.

Choosing AMT for custom plastic manufacturing services in Singapore

AMT offers a seamless service from tooling, molding, to shipping, decreasing waiting times and easing supplier oversight. It’s perfect for manufacturers and OEMs in Singapore who want trustworthy custom plastic production.

Single-source contract manufacturer

Single-source partners reduce handoffs and keep quality consistent. In-house toolrooms and presses suit medical, automotive, and electronics clients.

Protecting IP with Regulatory Know-How

Strong IP custody and clear compliance are vital in regulated spaces. AMT follows strict protocols for managing designs and molds safely and is experienced with US FDA and EMA standards, ensuring safe and confident product launches.

What Proves the Capability

AMT has earned respect through various certifications like ISO 9001 and ISO 13485, plus patents and awards for engineering and manufacturing.

| Core Capability | What it delivers | Why it matters |

|---|---|---|

| Integrated tooling and molding | Faster validation with fewer quality gaps | Cuts time-to-market for precision parts |

| Assembly + Supply-Chain Integration | End-to-end logistics and vendor coordination | Streamlines production and lowers inventory risk |

| IP protection protocols | Secure custody and controlled access | Preserves competitive advantage for customers |

| Regulatory Compliance | FDA/EMA-aligned processes with industry norms | Enables smooth approval for medical and automotive parts |

| Technical credentials | Certifications, patents, and documented inventions | Demonstrates reproducible excellence in production |

Partnering with AMT gives teams proven molding strategies and deep process insight. Regional networks in Asia support growth and resilient supply.

When looking into custom plastic manufacturing services, choosing a partner like AMT is smart. Beyond IP protection, they carry the right credentials.

The Final Word

A fully integrated model plus multi-disciplinary depth gives AMT a solid foundation for Singapore manufacturers. Since 1990, AMT’s integration has shortened waits and simplified complex supply chains. AMT’s one-stop solution is why many OEMs see it as the top choice for complex components.

AMT’s expertise stands out in high-precision injection molding. Advanced methods—micro molding, multi-shot—ensure reliable parts for medical/auto/electronics. Industry 4.0 integration minimizes waste and tightens precision.

ISO 9001/13485, IATF 16949, cleanrooms, and a rising patent count prove AMT’s quality commitment. Technical skill plus supply-chain efficiency make AMT a key Singapore partner for custom plastic parts.